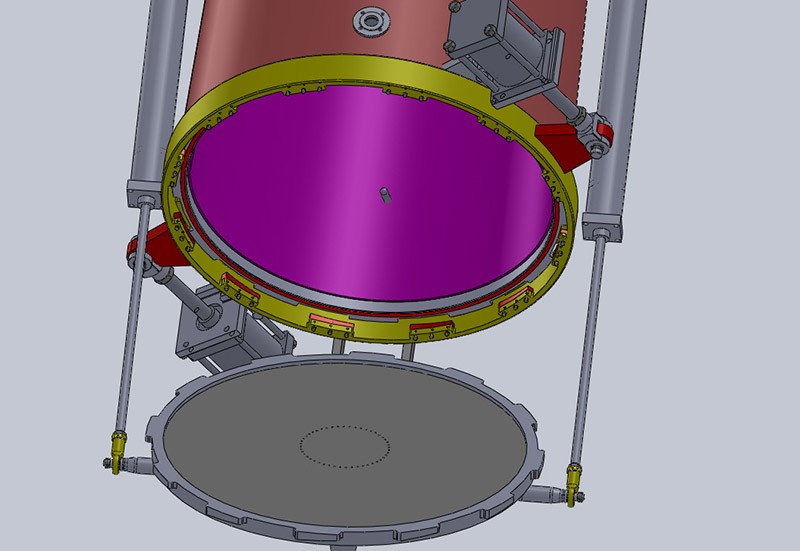

Leaf Extraction Machine

- JOSTON

- WENZHOU, CHINA

- 35 DAYS

- 20 SETS/MONTH

the machine is wedley using the solution to extract the medicine ingredient from the leaf raw material.likee the oliver leaf ,tea leaf etc,stevia leaf etc.

leaf extraction machine is used to extractor the stevia leaf ,tea leaf ,olive leaf ,ginkgo leaf etc raw material.

The working principle of the leaf extraction tank is a simple decocting process. The Chinese herbal medicine is soaked in water, heated by steam, and after a certain period of time, the effective ingredients are extracted. The decocting time is determined by the performance of different materials. The feeding amount can't be unified because the shape of the Chinese herbal medicine and the difficulty of effective component extraction are different.

The new process of extraction and concentration of traditional Chinese medicine is completed at one time, and the high-temperature decocting process with pressure in the extraction tank under normal pressure is improved. The low-temperature extraction and concentration are carried out by using vacuum negative pressure to make the extraction tank under low temperature The internal working temperature is controlled at 60 ~ 80 ℃, the concentration temperature is controlled at 50 ℃ ~ 70 ℃, which can keep the effective ingredients of traditional Chinese medicine from evaporation. At the same time, the steam generated from extraction and concentration is condensed by a hot cooler and returned to the extraction tank, which is added to the medicine as a new solvent. The new solvent passes through the medicine layer from top to bottom, playing a dynamic percolation role, dissolving the soluble substances of the medicine to the bottom of the extraction tank and entering the concentrator for concentration. According to the practice and research for many years, under the action of the heat of vacuum low temperature vaporization, the greater the concentration difference is, the higher the extraction rate of the effective components is. According to the corresponding model and specification, the original solvent in the extraction tank is replaced once in a proper time, so that the solute in the extraction tank and the solute in the extract can maintain a higher concentration difference in unit time.

leaf extraction machine characteristics:

1. Fully closed cycle extraction and concentration can save energy by 0.3-0.5 times.

2. According to different drugs, reduce the solvent by 0.5-1 times, and increase the dosage by 20% - 60%. The paste yield was increased by more than 10%.

3. Hot reflux, extraction under normal pressure, concentration at low temperature, shortening the production time by more than 1 / 3.

4. Suitable for water extraction or alcohol extraction.

5. Cancel intermediate storage, etc,

6. if the digital display regulator is added, the temperature can be adjusted.

7. The equipment ointment processing equipment has compact structure, convenient operation and 50% saving of floor area.