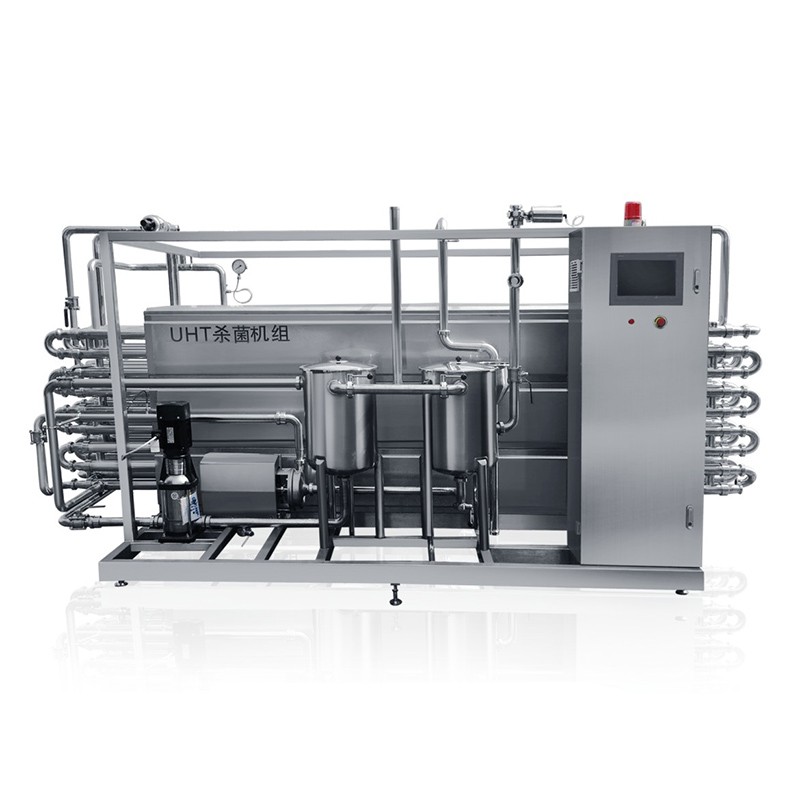

Cip Machine

- JOSTON

- WENZHOU, CHINA

- 35 DAYS

- 20 SETS/MONTH

CIP machine is used to wash the equipment and pipeline automatic

CIP (clean in place ) machine is widely used to washing the production equipment and pipeline in pharmaceutical ,dairy ,juice ,food ,beer ,wine etc filed .

CIP machine including the following unit :

1).CIP wshing tank : as the process requirement ,we can make single tank ,double tanks ,three tanks or four tanks group .as usual the CIP tanks can be work as the

acid solution tank ,alkali solution tank ,hot water tank ,pure water tank .

2).CIP heating system : can use steam to heat via the heat exchanger or tank jacket or by electrcial .

3).CIP washing pump .

4).CIP back pump

5) control instrument : PH sensor ( conductivity meter ) ,temperature sensor ,pressure gauge ,flow meter etc

6) control panel system

7) pipeline and valves for CIP system

CIP machine can be control automatic ,semi-automatic and manual according to the production requirement .

Automatic type CIP machine can control automatic for the following parameter:

1) Acid solution and alkali solution dosing by diaphragm pump according to the PH sensor data automatic.

2) Washing solution temperature can adjustable automatic.

3) Washing time can automatic set .

4)Washing proceed can be automatic set .

CIP system working principle is to control the opening and closing of the steam valve by measuring the temperature sensor; to control the opening and closing of the water valve by measuring the level of the liquid through the pressure transmitter; to control the pneumatic diaphragm pump dosiong acid/alkali by measuring the conductivity meter.

The overall control process is water filling to the tank --acid tank (alkali tank ) PH adjust- water heating - hot water washing - alkali washing - hot water washing - acid washing - hot water washing.

CIP wahsing proceed setting parameter for reference :

NO | Item | Time(M) | Temperature | Remark |

1 | Pre-wash | 10 | Room temp.or 50°C | Tap Water or pure water |

2 | Alkali solution | 10-30 | 60-80°C | 2-4%NaOH solution |

3 | Hot water | 10-20 | 60-80°C | Tap water or pure water |

4 | Acid solution | 10-30 | 60-80°C | 2% HNO3 solution |

5 | Final wash | 15 | 60-80°C | Pure water |