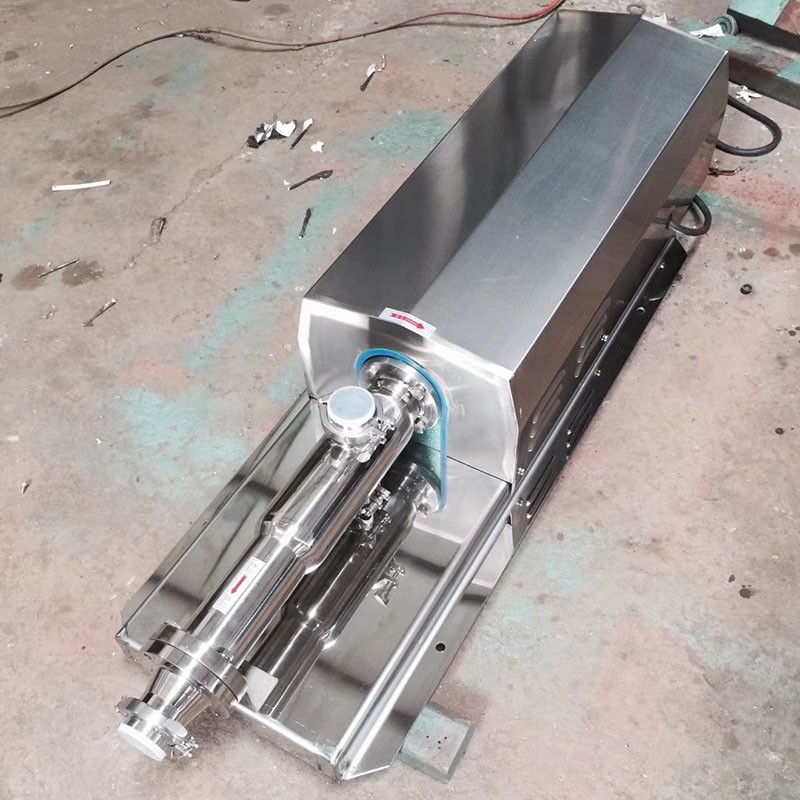

Diaphragm Pump

- JOSTON

- WENZHOU, CHINA

- 15 DAYS

- 40 SETS/MONTH

pneumatic diaphargm pump is used to transfer the liquid product or viscosity products .it donot need electrical driver ,also not need petrol & oil driver .

pneumatic diaphragm pump due to without electrical motor ,so it can be used in the explosion-proof room which have restricted with the electrical .

also it without the mechanical seal ,so it can be working under the solution transfer which is not continous flow .

Working principle:

In the two symmetrical working chambers of the diaphragm pump, each is equipped with an elastic diaphragm, and the coupling rod forms the two diaphragms into a whole. After the compressed air enters the air distribution valve from the air inlet joint of the pump, the diaphragm in the two working chambers is pushed to drive the two diaphragms connected by the coupling rod to move synchronously. At the same time, the gas in the other working chamber is discharged out of the pump from the back of the diaphragm. Once the end of the trip is reached. The air distribution mechanism automatically introduces the compressed air into another working chamber and pushes the diaphragm to move in the opposite direction, thus forming the synchronous reciprocating motion of the two diaphragms. Each working chamber is equipped with two one-way ball valves. The reciprocating motion of the diaphragm changes the volume of the working chamber, forcing the two one-way ball valves to open and close alternately, so as to continuously suck and discharge the liquid.

Performance characteristic :

1. There is no need for irrigation and water diversion. The suction head is up to 5m, the lift is up to 50m, and the outlet pressure is ≥ 6kgf / C ㎡;

2. The flow is spacious and the passing performance is good. The maximum particle diameter allowed to pass is up to 10 mm. When pumping mud and impurities, there is little wear on the pump;

3. The head and flow can be adjusted steplessly through the opening of the air valve (the air pressure can be adjusted between 1-7 bar):

4. The pump has no rotating parts, shaft seal, diaphragm j| and other pumped media are completely separated from the moving parts and workpiece media of the pump, and the transmitted media will not leak out. Therefore, when toxic, easy to play or corrosive media are pumped, environmental pollution and personal safety will not be caused;

5. No need to use electricity. It is safe and reliable to use in inflammable and explosive places;

6. It can work in the medium:

7. It is convenient to use, reliable to work, and it only needs to open and close the gas valve to start and stop. Even if there is no medium operation for a long time due to an accident or the pump stops suddenly, it will not be damaged. Once it is overloaded, the pump will stop automatically, with self-protection performance. When the load returns to normal, it can start and run automatically;

8. The pump has simple structure, few wearing parts, simple structure, convenient installation and maintenance. The medium transported by the pump will not contact with the moving parts such as the valve and the connecting rod. Unlike other types of pumps, the performance of the pump will gradually decline due to the wear of the rotor, piston, gear, blade and other parts:

9. It can transport viscous liquid (viscosity is below 10000 centipoise):

10. This pump does not need oil lubrication, even if it is idle, it has no effect on the pump, which is the biggest feature of this pump